In my previous article, I discussed the different series and model designs of the PC-12. This article will focus on the single biggest hurdle that Pilatus had to overcome in marketing and selling the PC-12. Early aircraft engines were underpowered and unreliable. Multiple engines were required on an aircraft to carry a nominal payload to their required destinations. Couple this with the unreliable nature of the engines and the mentality of “the more engines the better” was born. This mentality gave rise to “multi” multi-engine aircraft such as the DC 4, 6 and the B-52. As aircraft production rates continued to grow, so did the monetary and mental investment into the multi-engine mindset. Given the high failure rate of these early model engines, OEM salesman drove the perception that a single engine aircraft was not safe. The final piece to the anti-single engine stigma was most pilots learned to fly in single engine aircraft and their goal was to advance to a multi-engine model. The thought of moving back to a single engine seemed like a step backward.

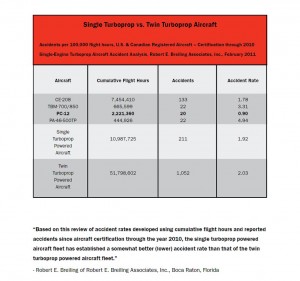

From an operational perspective, single engine aircraft are considerably cheaper to operate and maintain. From a piloting perspective, single engine aircraft are considered easier to fly than their multi-engine counterparts. When a multi-engine aircraft has an engine incident or failure, it has issues with asymmetric thrust, which causes further issues with yaw and roll. Obviously, this same scenario for the single engine pilot has its “issues”. While the single engine aircraft is much more controllable, you are faced with the issue of not having any available thrust. With this in mind, the real issue then comes down to engine reliability. As technology advanced, the engine failure rate declined. Pilatus believed with the increased reliability of the turbine engine, it was possible to design, produce and sell the single engine concept to the GA community. The data below supports their belief:

The key to these numbers for Pilatus was there selection of the Pratt & Whitney Canada’s PT6A-67 engine. The latest version, the 67P, produces 1744 shaft horsepower (shp), but it is flat rated to 1200 shp. Rating the engine at only 70% means the stresses and temperatures it was designed to withstand are never imposed on it, reducing engine wear and maintenance costs. Finally, the aerodynamic development of the PC-12 allowed for sufficient driftdown capabilities in the event of an unlikely failure.

The battle to overcome the “multi-engine mindset” is far from over so Pilatus continues to improve the PC-12 in terms of operational capability, reduced operational costs, passenger comfort and overall safety rating. As the old movie line says, “If you build it, they will come.”

John Hall

Will be interested in your comparison of the PC12 and Denali when certified. FYI— owned and loved my 525 but got fed up with the service costs (bad Service Center experiences) and just too small a cabin. Have had great experience with my PC12 for the last 2 years—and now charter when have longer trips. Though once owning a jet, always miss it. Maybe a CJ3 share soon.

We are keeping a close eye on the Denali program as well and will provide updates as they become available. Interesting engine choice, we'll see how that works out.