Citation Ultra: Cessna’s Popular Workhorse Still Earning Its Keep by Mark Schweibold

Does the business aircraft industry’s best-selling Cessna Citation Ultra still retain its reputation as the industry standard in the light jet market? Its origins distilled from experience gained in the original 500 series Citations, the Ultra still offers better short-field performance than virtually any other turbofan aircraft with the same number of seats. Its flying qualities and slow-speed handling traits probably are as forgiving as those of any current production airplane with two engines. This straight wing Citation is a performer. The Ultra, loaded to maximum takeoff weight, can depart from a 3,200-foot runway, climb to FL 410 in 23 minutes and fly more than 1,500 nm at 400-plus knots. Slow down to 370 KTAS and it will fly between virtually any two points in the United States with one fuel stop—against the most probable headwinds. Speed, range and short field performance help to explain why it was the best-selling business jet during its production run.

The Ultra became the epitome of “Sensible Citation”. You can cost-effectively update the avionics to modernize and enhance the Ultra’s capabilities. The Ultra’s Pratt Whitney JT15D-5D engines lack a little efficiency versus modern powerplants; however, their durability and robustness are proven over millions of flight hours. Its cabin is spacious and the appointments tastefully sheik featuring the perfect length for a double club configuration. Today, pre-owned Ultras sell between $1M-2.5M which is a mind-boggling discount from its new $6M selling price. If you could use a low-cost, efficient aircraft to safely haul 8 passengers in comfort from just about any airport with guaranteed direct operating costs, the Citation Ultra needs careful evaluation and definitely be on your short-list.

PERFECTING PERFORMANCE

The Ultra, being the fastest straight wing Citation, is close to 90 knots faster than the Citation 500 that made its debut in 1969. It takes a close look, however, to see how Cessna accomplished this considerable leap in performance. The original Citation 500, I and II were fitted with NACA 23000-series airfoils, not unlike those used on King Airs. Time-proven 23000-series airfoils have relatively benign stall characteristics, but compressibility drag rises sharply above cruising speeds of 0.65 to 0.67 Mach. At 0.70 Mach, the 23000-series airfoil runs into a virtual drag wall. This fact wasn’t a problem in early Citations because Pratt & Whitney Canada’s first-generation JT15D turbofans only produced enough thrust to push them to 335 to 375 knots. As a result, the wing and the engines actually were quite well matched.

As Pratt & Whitney developed higher thrust versions of the JT15D engine, however, Cessna recognized the need to develop a wing with a higher cruise speed. Fitting the Citation with a clean sheet wing was out of the question. Cessna’s customers would have balked at the price increase. Instead, Cessna’s aerodynamicist collaborated with NASA’s Richard T. Whitcomb, father of the supercritical wing, to develop a modified wing that would use the existing wing spars. While not a true supercritical wing, the new airfoil incorporates a larger leading-edge radius and a relatively flat upper surface. Airflow over the top of the wing is accelerated more mildly than with the 23000-series wing, and lift is distributed over a longer chord section that results in less compressibility drag.

The tangible outcome for operators is a 0.08 Mach increase in maximum cruise speed. This modified wing has a maximum cruise speed of 0.75 Mach—equivalent to 430 knots depending on cruise altitude. The wing also features a cuffed, tapered inboard section with a longer chord adjacent to the fuselage. This effectively reduces the thickness-to chord ratio at the wing root, thereby resulting in an even milder pressure distribution where the wing joins the fuselage.

This design feature reduces wing-to-fuselage interference drag. Cessna equipped the modified high speed wing with four-section Fowler flaps that actually reduce V-speeds up to 10 knots compared to the Citation II’s wing that is fitted with two-section hinged flaps. As an added bonus, the new wing’s greater internal volume holds about 800 pounds more fuel. The new wing first went into production on the Citation SII in 1984 though thrust output from its engines limited its maximum cruise speed to just over 400 knots. In 1988, the Citation V remedied that shortcoming. Its JT15D-5A engines pushed maximum cruise speed up to 427 knots. The Ultra, introduced in 1994, just upped the ante. Its -5D turbofans enable it to climb faster to cruise altitude and, thus, reducing block times on trips of all lengths.

ROBUST STRUCTURE AND SIMPLE SYSTEMS

In spite of the Ultra’s impressive performance, it remains true to Cessna’s goal of building a low operating cost turbofan business airplane with straightforward systems. Aluminum is the primary structural material used in the airframe. Composites are used for some secondary structures, such as the ailerons and wing flaps. The fuselage has the familiar Citation circular cross section, and the wing structure uses a classic, rigid torque box formed by main and rear spars, ribs, skins and stiffeners. This classic design is meaningful as the aircraft ages since the materials and structural engineering are well-proven providing maximum protection against any high cycle fatigue issue.

The vault-design, forward-entry door measures 50.7 inches high by a maximum 23.5 inches wide near the bottom. A folding ladder, hinged at the door sill, is used for passenger boarding. Cessna also offers an optional 35-inch wide, two piece clamshell door for special missions. On the right side of the fuselage, directly across from the entry door, is an FAA Type III plug design emergency exit. Systems simplicity is one of the Ultra’s strongest selling points. The fuel system has left and right wing tanks that feed the left and right engines. Each wing tank is refueled through an over-wing filler port. As there are no fuel heaters, an anti-icing additive is required for fuels that are not pre-mixed. Electrically driven fuel-boost pumps are used for engine starting, cross-feed and to back up the jet pumps during abnormal operations.

A 24-volt, 40-amp/hour NiCd battery supplies electric power for engine starting and emergencies. Each engine has a 300-amp starter-generator. DC electrical power is used for most electrical and avionics functions, except for vertical, directional and yaw rate gyros, which depend upon AC power. An emergency battery supplies power to the pilot’s-side directional gyro, the standby attitude indicator and HSI, N1 fan speed tachometers, the com 1 and nav 2 radios, standby pitot and static heaters, both audio panels and the overhead flood lights. Each wingtip has a landing light and recognition light, plus each main landing gear strut has a taxi light. Logo lights illuminate the vertical fin. The -5D engines produce enough surplus bleed air for cabin pressurization and air conditioning, plus engine inlet, inboard wing leading edge and windshield anti-ice. Conformal deice boots, inflated by low-pressure bleed air, protect the outboard wing and horizontal stabilizer leading edges against ice accumulation.

There is no APU. However, the right engine has a unique bleed-air ground feature. When selected, this triples the air flow from the right engine for heating or air conditioning, thereby improving temperature control. A high-capacity, electrically-powered, vapor-cycle air conditioner having both front and rear evaporators augments the air-cycle machine for cooling. The vapor-cycle air conditioner, which can be powered by a 28-volt GPU, can be used in flight up to 18,000 feet msl. There is a single-zone thermostat, but the air flow between the cockpit and the cabin can be varied to produce a comfortable temperature in each location.

The hydraulic system is an on-demand, open-center design in which engine-driven hydraulic pumps continuously circulate fluid at low pressure, thereby minimizing the potential for leaks. When hydraulic pressure is needed to power the landing gear, wing flaps, spoilers or reversers, a bypass valve in the return line closes, causing the pressure to increase to 1,500 psi. As soon as the desired action is complete, the bypass valve opens and the system returns to low pressure operation. A separate electrically driven hydraulic pump charges the anti-skid, power brake accumulator. An emergency pneumatic brake system provides a back-up for the hydraulic power brakes.

The primary flight controls are manually operated with console-mounted trim wheels for all three axes. The electric pitch-trim system can be operated by a conventional split switch on the pilot’s yoke. Nose wheel steering is connected to the rudder pedals by means of spring links that provide +/-20 degrees of steering authority. Differential power and braking can be used for tighter turns. The flaps have four detents: retracted, seven degrees (takeoff), 15 degrees (takeoff and approach) and 35 degrees (landing). The electrically controlled and hydraulically powered speed brakes have two positions—retracted or extended.

About five to 10 percent of Cessna’s customers ordered the optional gravel runway kit. This option features a nose-wheel spin-up system that prevents debris from being kicked up into the engines when the nose wheel touches down on the runway, along with antenna guards and flap shields. This option can always be added later if the need arises.

DIGITAL AVIONICS

Honeywell’s Primus 1000 forms the basis for the Ultra’s avionics package. Three, eight-by-seven-inch CRT displays, made up of left- and right-side primary flight displays (PFDs) plus a multifunction display (MFD) in the center, occupy the panel. New to this year’s model are the formerly optional, now standard, equipment—left- and right-side Primus II radio management units that flank the MFD—indicating that Honeywell com/nav/ident radios were the latest production standards. (Collins Pro Line II radios were standard equipment in previous Ultra aircraft.) The relevant controls are located directly on the screens’ faceplates to improve pilot hand-eye coordination and flight performance.

The upper LCD is a standby EADI with air-data tapes, and the lower is a standby EHSI. These solid-state systems replace the electromechanical standby instruments that were used in older 560s. The standard pedestal houses an AlliedSignal GNS-XL one-box FMS with a GPS approach capability, in place of the GNS-XES that lacked a TSO C129 GPS sensor. Ultra customers also can choose a Universal Avionics UNS-1Csp (a box that was certificated on the Ultra in mid-1996) as a standard option. The Primus 1000 EFIS software has been upgraded to provide for the automatic course deviation needle scaling required for GPS non-precision approaches.

Both the AlliedSignal and Universal FMS’s offer a GPS non-precision approach capability, but the UNS-1Csp has more performance features, such as full SID/STAR guidance, all ARINC 424 procedure legs, multiple waypoint vertical navigation and coupled vertical path navigation on non-precision approaches. Ultra FMS’s have the ability to remain current and are upgradable. Ultra serial number 560-0354 incorporates the Universal UNS-1ESPW FMS which includes the WAAS enabled super flight management system containing a precise, augmented GPS receiver capable of navigating approaches to ILS minimums.

Other standard avionics include the Primus 1000 digital flight-guidance system, dual Honeywell mechanical and vertical gyros, dual digital airdata systems, dual Primus II radio audio-control panels with digital audio buses, a Primus 650 weather radar and an AA 300 radio altimeter. A Loral/Fairchild CVR and an Artex ELT110-4 also are included in the standard package. Avionics options include AlliedSignal Global Wulfsberg AFIS, an HF transceiver, Coltech Selcal, AlliedSignal TCAS I, II and GPWS, and a Fairchild FDR.

Cabin options include a Hughes MagnaStar or AlliedSignal Global Wulfsberg Flitefone air-to-ground radiotelephone, an Airshow 400 cabin entertainment and real-time information system, and other airborne office equipment.

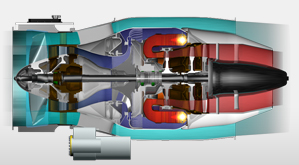

P&WC JT15D-5D ENGINES

Pratt & Whitney Canada’ family of JT15D light turbofan engines have become one of the most reliable turbine powerplants ever designed with the series logging over 45 million flight hours. The original -1 engine is a study in simplicity. The gas generator core consists of a single centrifugal flow compressor, combustor and single high-pressure turbine. Most of the exhaust energy is absorbed by a two stage, low-pressure turbine that, by means of a concentric shaft, powers a simple bladed fan in the front of the engine. Because the fan produces most of the thrust, the bypass ratio is 3.3:1. A relatively low overall pressure ratio, no flat-rating and the relatively high bypass ratio result in a comparatively high thrust-lapse rate for the -1 engines. They lose more than 80 percent of their takeoff thrust at high-altitude cruise. P&WC started to remedy that shortcoming with the -4 engines. They are fitted with an additional low-pressure turbine stage and a single, axial flow supercharger compressor on the N1 shaft aft of the fan. This boosts the overall pressure ratio, but it also reduces the bypass ratio to 3:1. The result is slightly higher specific fuel consumption, but more high-altitude thrust. Internally, the -5 engines are similar to the -4 engines, but they also have the following features: a wide-chord fan, a more robust core, improvement in high-pressure compressor aerodynamics, a fine-tuned exhaust nozzle and a higher overall pressure ratio. These engines retain almost 25 percent of their thrust at high altitude.

fan produces most of the thrust, the bypass ratio is 3.3:1. A relatively low overall pressure ratio, no flat-rating and the relatively high bypass ratio result in a comparatively high thrust-lapse rate for the -1 engines. They lose more than 80 percent of their takeoff thrust at high-altitude cruise. P&WC started to remedy that shortcoming with the -4 engines. They are fitted with an additional low-pressure turbine stage and a single, axial flow supercharger compressor on the N1 shaft aft of the fan. This boosts the overall pressure ratio, but it also reduces the bypass ratio to 3:1. The result is slightly higher specific fuel consumption, but more high-altitude thrust. Internally, the -5 engines are similar to the -4 engines, but they also have the following features: a wide-chord fan, a more robust core, improvement in high-pressure compressor aerodynamics, a fine-tuned exhaust nozzle and a higher overall pressure ratio. These engines retain almost 25 percent of their thrust at high altitude.

Notably, the -5 engines have the lowest bypass ratios in the JT15D family, but they also have the best thrust-specific fuel consumption at high altitude because of their higher pressure ratios. The -5D is the most highly evolved of the -5 series, a 3,350-pound thermodynamic rated turbofan that is flat-rated at 3,045 pounds of thrust for takeoff to 27°C (80°F). The -5D uses integral blade rotors, machined from a single piece of metal, for the fan and axial supercharger compressor, plus it is fitted with high-temperature tolerant, single-crystal high-pressure turbine blades. With the widest chord design in the -5 family, the fan is shrouded by a Kevlar belt for better sealing and lower weight. The result is five percent more thrust than the Citation V’s -5A engines produce and a one-percent improvement in specific fuel consumption at high-altitude cruise. At 0.80 Mach, 40,000 feet (uninstalled), the -5D engine produces 737 pounds of thrust with a 0.868 lb/lb tsfc. (That’s almost 98 percent of the high-altitude thrust output of the AlliedSignal TFE731-2 that powers 30-series Learjets.)

Having a 2.1:1 bypass ratio could have had an unwanted side effect: noise for airport neighbors. The fact is Ultra’s climb performance means it is still one of the quietest turbofan aircraft on takeoff, especially when you are flying a noise-abatement departure profile. Cessna claims the Ultra can whisper over the airport neighbors at 67.1 dBA if the thrust is pulled back to 80.2 percent N1 during the initial climb.

PASSENGER AMENITIES

At its debut, the Ultra had the longest cabin of any straight-wing Citation. The cabin is 1.5 feet longer than the cabin of a Bravo and a full four feet longer than the original Citation 500. A five-inch dropped aisle, which extends from just aft of the cockpit throughout most of the seating area, increases headroom to 55.3 inches. The extra length allows the cabin to be configured in double club, with enough room left over for a full-width, aft lavatory. Pyramid cabinets in the center cabin, between the two club sections, provide most of the onboard storage for small stores.

At least half of the Ultras are alternately configured with a center club section, with three to four other seats facing into the club. This configuration permits the aft club seats to be mounted on seat tracks that allow them to be moved back an additional seven inches for greater legroom in the center club section. The center club is flanked by a forward refreshment center on the left and an aft-facing chair adjacent to the right-front cabin bulkhead. Two forward- facing chairs are placed behind the club section and ahead of the lavatory bulkhead.

At least half of the Ultras are alternately configured with a center club section, with three to four other seats facing into the club. This configuration permits the aft club seats to be mounted on seat tracks that allow them to be moved back an additional seven inches for greater legroom in the center club section. The center club is flanked by a forward refreshment center on the left and an aft-facing chair adjacent to the right-front cabin bulkhead. Two forward- facing chairs are placed behind the club section and ahead of the lavatory bulkhead.

In our opinion, the interior quality is still top notch. John Hall stated, “It’s in keeping with the Ultra’s then $6-million price tag and the best we had seen in a 500-series Citation.” The overhead and sidewalls are covered in seamless sheets of fabric, and indirect lighting makes the cabin seem larger than its measurements reveal. The side rails, finished with wood laminates or optional veneers, have cup holders for each seat. The lower cabin sidewalls are covered in durable, embossed leather or a choice of other long-wearing fabrics. The wool carpet has a strong silk backing and is fireblocked. Aircraft Modular Products of Miami built the passenger chairs, which Cessna covered in a choice of leathers. The chairs are equipped with lap and shoulder belts, adjustable in pitch, rake and track, and have retractable headrests. The seats also swivel on their pedestals and contain small storage drawers in the pedestal bases.

In our opinion, the interior quality is still top notch. John Hall stated, “It’s in keeping with the Ultra’s then $6-million price tag and the best we had seen in a 500-series Citation.” The overhead and sidewalls are covered in seamless sheets of fabric, and indirect lighting makes the cabin seem larger than its measurements reveal. The side rails, finished with wood laminates or optional veneers, have cup holders for each seat. The lower cabin sidewalls are covered in durable, embossed leather or a choice of other long-wearing fabrics. The wool carpet has a strong silk backing and is fireblocked. Aircraft Modular Products of Miami built the passenger chairs, which Cessna covered in a choice of leathers. The chairs are equipped with lap and shoulder belts, adjustable in pitch, rake and track, and have retractable headrests. The seats also swivel on their pedestals and contain small storage drawers in the pedestal bases.

Precision Pattern in Wichita built the cabinetry, also first rate, which represented a radical improvement over the furnishings of early Citations. The refreshment center, for example, is made of strong, durable and lightweight hollow core composites covered with a choice of high-gloss-finished wood laminates and wood veneers and inlays. Inside the refreshment center is hot and cold-beverage storage, a relatively large, stainless-steel ice bin, rolling racks for canned beverages, space to store miniatures, and a 16-inch-wide rollout drawer that holds small catering trays. It also has a generously sized, leak-proof, stainless-steel waste container located in a deep pull-out drawer.

The aft lavatory’s toilet has a removable waste container. An externally serviced lavatory was not available and would have added substantially to weight and price. Cabin options included upgraded woods and leathers, additional cabinets for magazines and small stores, and a lavatory vanity cabinet with a sink providing fresh water. An Airshow cabin entertainment system with individual, full-color, flat-panel video screens and audio jacks was also a popular option.

The Ultra retains the straight-wing Citation’s unique, nose external luggage compartment, which was actually carried over from its propeller-driven twins. It is ideal for briefcase missions because of its shallow floor, 15 cubic feet of volume, and accessibility by means of left and right baggage compartment doors. Surprisingly, you can fit two professional sets of golf clubs in the nose compartment baggage. You can actually fit a full eight sets of golf clubs in the Ultra plus baggage – one of Russ Meyer’s legacies for the sake of many Citation owners that are golfers: he demanded the Ultra meet a dual foursome prerequisite. A separate 28-cubic-foot aft external compartment holds 500 pounds of luggage. Inside the cabin, on the left side of the lavatory, equally impressive is an additional 26 cubic feet of baggage volume that will hold 600 pound.

ULTRA SERIAL NUMBER 560-0354 FLYING IMPRESSIONS

The preflight on Ultra 560-0354 brought forward the pedigree this Ultra enjoys: One owner since new, no expenses spared, factory maintained and augmented by a professional flight department with a full time maintenance staff. It’s quickly evident this Ultra is as good as it gets and it shows in the details as well as the cosmetics. I begin to feel really comfortable very quickly. This feeling is natural in the Ultra as it’s one of those aircraft you wear quicker than most. It truly is a stable platform and once you’ve mastered the FMS, you’re probably 90 percent assured of a successful check-ride. Preflight chores reflect the design of the systems: simple and straightforward. Everything is within easy reach, but the Ultra’s low stance makes it a little tough to get to the fuel drains and brake-wear indicators. Starting an engine is easy. Turn on the battery and AC power switches, touch an engine-start button and wait for the N2 turbine rpm gauge to read eight to 10 percent. At that point, just advance the thrust lever into the idle detent, and normally all other start functions, including the starter-to-generator transition, are automatic. (If you want to preheat or pre-cool the cabin, you may want to start the right engine first to take advantage of the triple-bleed-air flow rate of the bleed air ground feature.) Citations use a generator-assisted cross start to help start the second engine when using battery power. Bump up the operating engine to precisely 52 percent N2 turbine rpm, and you’ll be assured that it supplies just the right amount of supplemental electrical current. Use more than 53 percent, though and you can damage the generator drive.

In the Ultra, however, pilots do not have to fine-tune the high-speed idle for cross start. Flick the ground idle switch from normal to high, and the N2 rpm increases to exactly the required speed. Flying Ultra serial number 560-0354 out of Huntingburg, Indiana (KHNB), our computed takeoff was a svelte 13,800 pounds—2,500 pounds below MTOW. Computing V-speeds and takeoff field lengths is a snap in Citations. Cessna publishes all the data in tables, so there are no cumbersome charts to plot and no fat-finger errors. The takeoff V-speeds were 86 KIAS for the V1 takeoff decision speed, 94 KIAS for rotation and 106 KIAS for the V2 one engine inoperative (OEI) takeoff safety speed. The computed takeoff field length was 2,680 feet. (If we had departed at MTOW, the takeoff distance would have been 3,560 feet, and V2 would have been 112 KIAS.) Once cleared for takeoff on Huntingburg’s Runway 27, I advanced the thrust levers to 97.3 percent N1. The Ultra responded like the racehorse Citation sprinting out of the starting gate.

The Airspeed quickly came alive, cross check, V1, rotate, V2, positive rate I scanned in an almost in a continuous stream. The pitch force at rotation was moderate. Our initial fuel flow on takeoff was 3,600 pph, and the initial climb rate was in excess of 5,000 fpm as we accelerated to the 200 KIAS Class D airspace speed limit. Once clear, we made the transition to a 250 KIAS/0.62 IMN climb schedule. Our fuel flow through 5,000 feet was 2,800 pph. The thrust levers have to be adjusted occasionally during the climb because the hydromechanical fuel controls lack digital computer sophistication. In a scant 20 minutes, we reached FL 410, and we were still climbing at 1,000 fpm as we began the level-off at cruise altitude. We set 98.1 percent N1 for high speed cruise, making no effort to conserve fuel, which resulted in a fuel flow of 1,190 pph.

The aircraft stabilized at 0.752 Mach—only 0.003 below redline. Our true airspeed was 433 knots, 14 knots faster than the book value for our weight and fuel flow. At lower weights, the Ultra will push through MMO at maximum cruise thrust. A quick check of the yaw stability revealed that, because of its additional thrust, the Ultra is more mildly damped in yaw than earlier straight-wing Citations. Passengers will appreciate use of the yaw damper, but it is not required for dispatch. In contrast, the Ultra is well damped in pitch and roll. On our descent from FL 410 to 15,000 feet for air work, we found that deploying the spoilers causes a mild nose-down pitching moment, resulting in an increase in airspeed. However, a combination of landing gear (VLO at 250 KIAS) and spoiler extension produces little nose-down pitching moment and descent rates in excess of 9,000 fpm when needed for emergency descents.

The Ultra’s stall behavior, as a result of the modified wing design, is not as gentle as in early Citations fitted with the 23000-series airfoils. A stick shaker warns of the impending stall, and the actual stall break is accompanied by noteworthy wing drop. When pressed beyond the initial stall break, the Ultra may exhibit a pronounced wing rock. However, if stall recovery is initiated at the first sign of stall buffet, there is little altitude loss and no loss of directional or roll control. In operations over the years, the Ultras have never suffered a safety incident for flight handling and that fact pretty much says it all. The four, large, trailing-edge, Fowler flaps produce a strong nose-down pitching moment when deployed, but as a pilot, you’d never know it. A flap/pitch trim interconnect compensator all but eliminates the pitching moment.

We headed for Louisville, Kentucky for instrument approaches and landing-pattern work. We set the speed bug at 100 KIAS for VREF, based on a landing weight of 13,000 pounds. Straight-wing Citations are not particularly slippery, so slowing down in the Ultra isn’t a challenge. You can maintain 250 KIAS until you are close to the initial approach fix, and then you can use a combination of flaps, spoilers and landing gear to quickly decelerate to the desired approach speed. That’s a nice flight characteristic for anyone transitioning out of a turboprop.

We found that relatively low thrust settings will maintain VREF speed on final, because the four-section flaps produce plenty of lift and yet only moderate drag. Over the threshold, we slowly pulled the thrust levers to idle and flattened the approach attitude in anticipation of the landing plunk. The Ultra’s short-travel, straight-leg oleos offer very little cushion at touchdown, and consistently smooth landings require plenty of practice. This flight facet forces you to bring your smooth commercial flying skills – no carrier landings in this plane – but, who doesn’t like a challenge?

Simulated OEI takeoffs and landings aren’t much of a challenge in the Ultra. The large rudder and relatively long fuselage offer excellent directional control, plus the engines are mounted close to the fuselage. As a result, there is no need for a rudder boost or bias system. After the pattern work, we returned to Huntingburg for a final landing, accompanied by another minor plunk at touchdown. Our total fuel burn for the 1.7-hour flight was 2,200 pounds.

PRICE AND VALUE

When it was selling new, the Citation Ultra was the most expensive offering in the light-jet market, but that didn’t slow its sales. Why? Ultra’s cabin cross section is pretty much standard for the light-jet class, but it offers eight passengers considerably more length than its competitors do. The Ultra offers strong range/payload performance in the light-jet class. Only the Raytheon Beechjet 400A offers more payload—and then by only 15 pounds. But, the Ultra can carry its maximum payload almost 250 miles farther than the Beechjet and much further in hot high conditions.

Runway performance is the Ultra’s strongest performance asset. On 1,000-mile trips, it has the shortest takeoff field distance. When loaded to maximum takeoff weight on a standard day, the Ultra needs only 100 feet more runway than the class-leading CitationJet Series: an aircraft that offers close to one-third less range. The Ultra’s hot-and-high performance is clearly better than any other light jet’s. Notably, when departing a 5,000-foot elevation airport, the Ultra doesn’t run into a second-segment OEI climb limitation until the OAT reaches 33°C (91°F). This fact is largely due to the Ultra’s relatively low wing loading.

Need even more climb performance? You can opt to depart at flaps seven degrees, instead of flaps 15 degrees. The takeoff field length increases to 5,050 feet—still the best in class—and you can depart at the full 16,300- pound MTOW at 40°C (104°F).

The Ultra’s wing aerodynamics, as indicated by its relatively low 0.755 MMO, impose a tangible drag penalty at high-speed cruise. In addition, the Ultra has more frontal and surface drag than its competitors because of its dimensions. The Ultra, however, currently has the most cabin volume in the light-jet class, along with a clear advantage in runway performance and competitive block-to-block speed. Judging by the aircraft’s sales success history, light-jet buyers are looking for exactly those qualities.

This fact is really important – especially with pre-owned aircraft – Cessna’s financial stability, continuous-improvement program and sustaining engineering commitment provides owners assurance that the Ultra will have a long and successful life beyond the foreseeable future. With 775 Ultras, V’s and Encores produced, its lineage has become one of Cessna’s most popular Citation aircraft. The pre-owned Ultra today presents owners an unprecedented opportunity for buying a safe, reliable, efficient, flexible transportation solution for meeting just about every mission parameter. Expect little no residual value loss at today’s prices. Even better, the aircraft can still be put in all of Cessna competitive operating cost programs that guarantee a cap on your flight expenditures. Purchasing an Ultra like serial 560-0354 with its quality pedigree assures future owners of a predictable, very rewarding and safe ownership experience.

To obtain an ownership cash flow analysis detailing the Ultra’s total ownership and operating costs during a five year period Click Here. If you would like additional details about Ultra serial number 560-0354 featured in this article Click Here.